Minuteman Flight Control Equipment and Engines

Flight control equipment on the Minuteman missile has changed with system evolution. There were flight control equipment improvements with each major system upgrade, from Minuteman I to Minuteman II, but the functions remain the same in each system. These functions are: 1) Maintain stable control of missile attitude during the powered boost and post-boost portions of flight; 2) Execute stagings on command from the guidance system; and, 3) Perform velocity and deployment maneuvers on command from the guidance system.

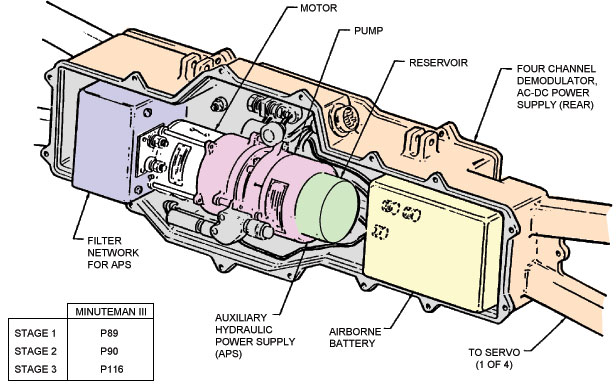

The P89 unit controls four movable exhaust nozzles, which in turn control orientation of the thrust vector, providing pitch, yaw, and RC. The P90 and P116 units control pintle valves which inject liquid into the nozzle exhaust stream, thus providing pitch and yaw control by deflecting the thrust vector. RC is accomplished by the ejection of hot exhaust gas through one of a pair of opposed nozzles perpendicular to the direction of the missile thrust vector.

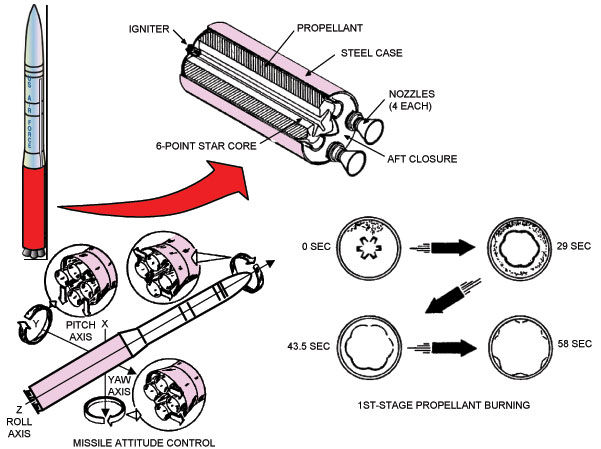

Stage 1 Propulsion

The first-stage motor (common to both Minuteman II and Minuteman III) consists of a steel motor case, a Class 1.3 solid propellant, an igniter, a steel aft closure with four movable nozzles, and a Nozzle Control Unit (NCU) for TVC. Each nozzle is capable of pivoting through an angle of ± 8 degrees from null, in a plane parallel to the motor center line and perpendicular to the pivot planes of the adjacent nozzles. The motor was designed and built by the Thiokol Corporation; the NCUs, which are part of the guidance system (Section Three), were designed and built by Rockwell International.A single high-performance solid propellant is cast into the motor case with a six-point star hollow core, which maintains thrust by keeping a constant surface area as the propellant burns away. The propellant consists of an ammonium perchlorate oxidizer, aluminum powder fuel, a polybutadiene acrylic acid binder, and an epoxy-resin curing agent.

The case serves as the missile structure with the inter-stage attached at its forward end and the skirt at the aft end. The closure and nozzles are insulated from the thermal effects of the chamber temperature by molded plastic, Buna-N rubber, mastic insulation, and high-density graphite parts. A low-temperature ablative epoxy insulation (Avcoat) protects the motor case exterior from silo launch, nuclear thermal, and aerodynamic heating. This material will be changed to Vamac rubber with booster production under the Propulsion Replacement Program (PRP).

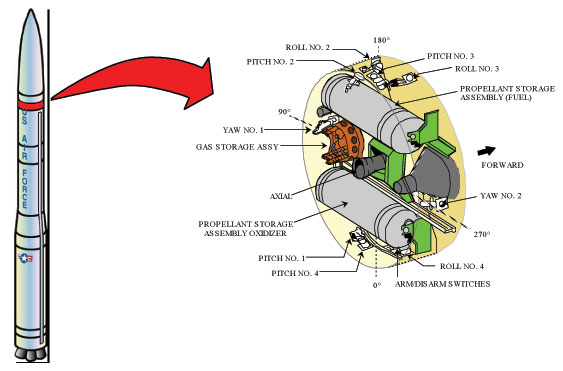

The nozzles, which move in response to commands issued by the guidance system to the NCUs, control the attitude of the missile during the first stage of flight. The pair of laterally opposed nozzles pivot up and down for pitch control. The vertically opposed pair pivot sideways for yaw control, and in opposition for roll control. All four nozzles are used to maintain roll stability.

P89 Nozzle Control Unit

Minuteman III Stage 1

Minuteman III Rocket Engine